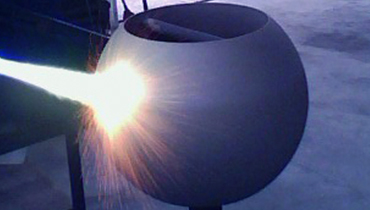

1. Coating process shall be HVOF

2. The thickness of coating after final grinding and polishing shall be minimum 200~ 400 micron.

3. The two seats shall be lapped with corresponding ball surface to assure full tightness.

4. 100% of sealing area to be dye penetrates examined.

5. Acceptable criteria: No visible defects

6. Typical composition: 86%Wc – 10%Co – 4%Cr (tungsten carbide e – cobalt- chromium)

7. Typical hardness 1050 HV

8. Tensile bound strength>10.000 Psi

9. For more detail see APENDIX D

10. Operating temperature is +200°C-350°C and sealing shall be flexible graphite.

|

|