Casting Ball Valve VS Forged Ball Valve

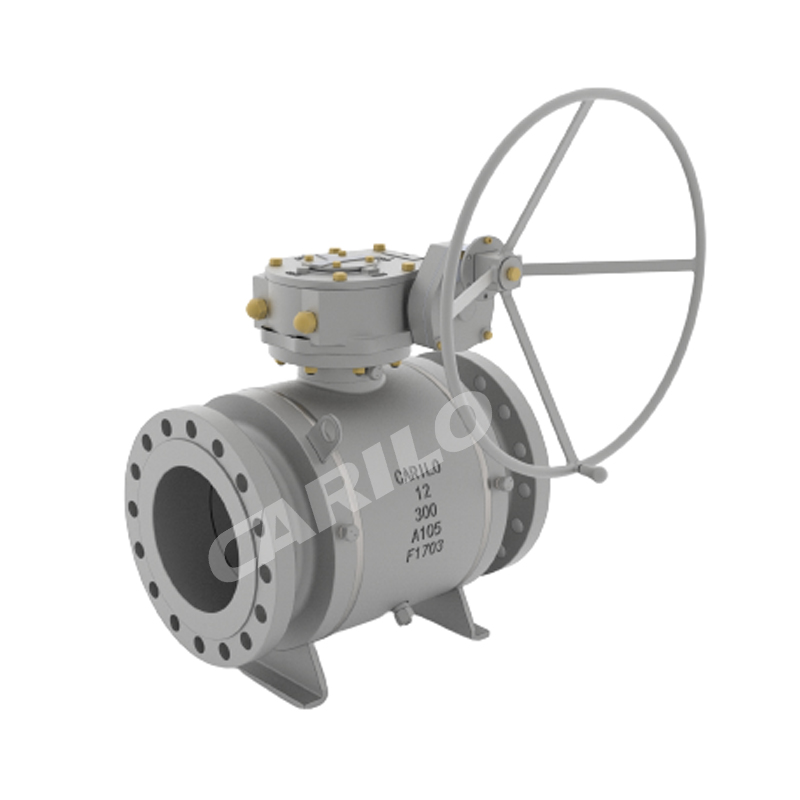

Casting Ball Valve:

Casting ball valves are produced through the casting process, where molten metal is poured into a mold

to create the valve body and components. This method allows for the production of complex shapes and

larger-sized valves at a lower cost. They are suitable for general industrial applications with moderate

operating conditions.

Forged Ball Valve:

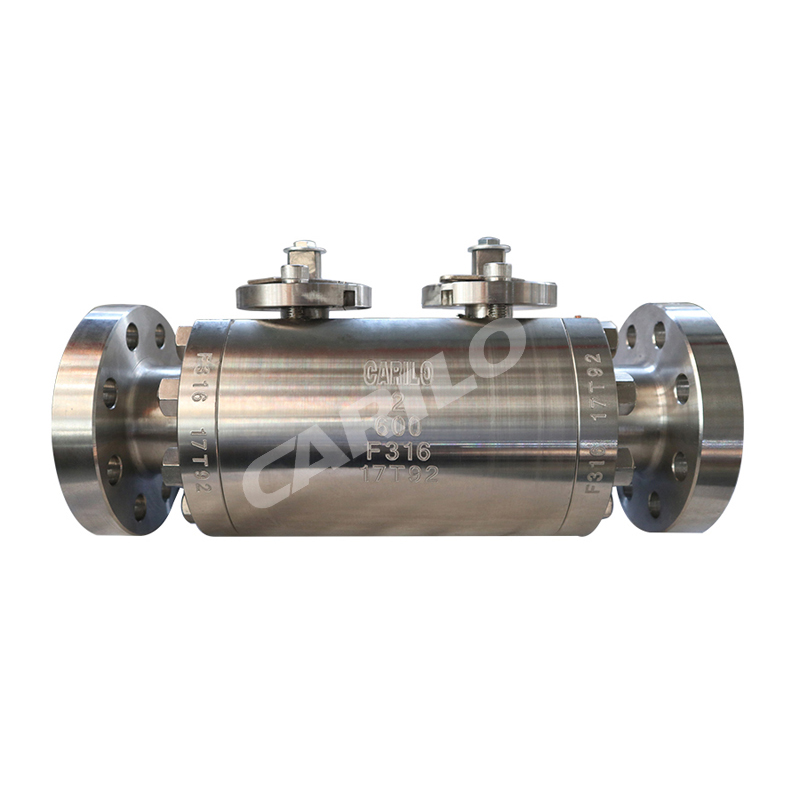

Forged ball valves, on the other hand, are manufactured through the forging process, where metal is

compressed and shaped under high pressure. This results in a more robust and compact structure, making

forged ball valves ideal for high-pressure and high-temperature applications. The forging process

enhances the mechanical properties, providing increased strength and resistance to mechanical stresses.

Choosing the Right Valve:

The selection between casting and forged ball valves depends on the specific requirements of the

application. For lower pressure and temperature applications with cost considerations, casting ball

valves offer a cost-effective solution. However, when dealing with high-pressure or high-temperature

conditions that demand superior mechanical properties, forged ball valves are the preferred choice.

Differences between DBB, DIB-1, DIB-2

DBB (Double Block & Bleed):

Provides reliable isolation and double block capabilities, ensuring enhanced safety in critical

processes.

DIB-1:

DIB-1 ball valves have DPE seats both upstream and downstream to provide a seal in both directions. For

the DIB-1 configuration, over pressurization of the cavity is avoided by the use of an external relief

valve. With the ball in the closed position and pressure on the upstream side, the cavity pressure will

increase in case of upstream seat failure. The cavity pressure will cause a double piston effect on the

downstream seat creating a second seal on the ball.

DIB-2:

For the DIB-2 configuration, one seat SPE and the other DPE, cavity over-pressurization is internally

controlled within the line. If the upstream seat leaks, then there is automatic cavity pressure relief

on the upstream side and the downstream seat will provide isolation due to double piston effect.

The types of end connection - RF/RTJ/SW/BW/NPT

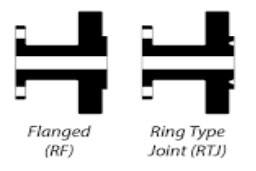

RF (Raised Face):

Commonly used for flanged connections, providing secure sealing and easy alignment.

RTJ (Ring Type Joint):

Ideal for high-pressure applications, ensuring robust sealing with metal-to-metal contact.

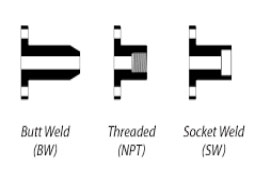

SW (Socket Weld):

Suitable for welded connections, offering reliable joint integrity and reduced stress concentration.

BW (Butt Weld):

Perfect for pipeline connections, ensuring strong and leak-resistant joints.

NPT (National Pipe Thread):

Versatile threaded connections, easy to install and suitable for various applications.

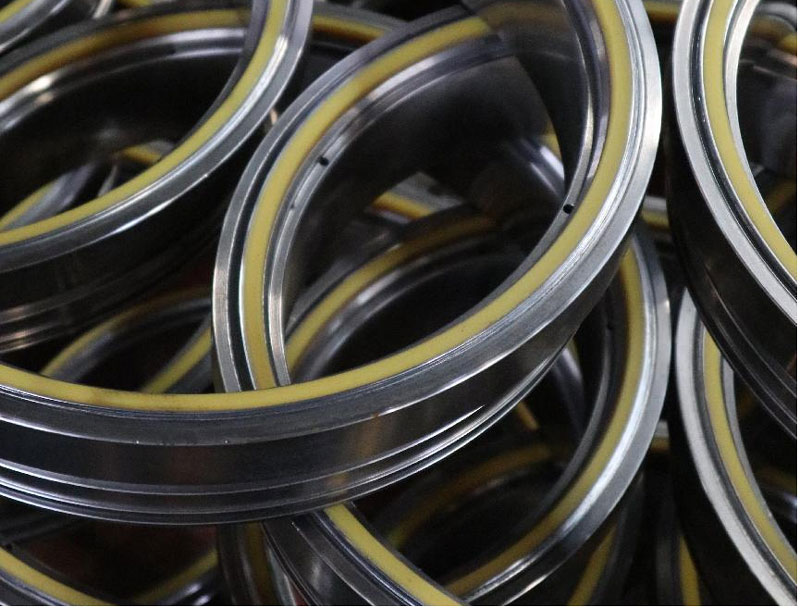

Soft seated VS metal seated

Soft Seated Ball Valves:

Soft seated ball valves feature a soft sealing material, such as PTFE (Teflon), which ensures excellent

sealing capabilities. When the valve is closed, the soft seat forms a tight seal against the ball,

preventing any leakage. Soft seated ball valves are ideal for applications that require bubble-tight

shut-off and low torque operation. They are commonly used in industries where leakage and environmental

concerns are critical factors.

Metal Seated Ball Valves:

Metal seated ball valves, as the name suggests, have metal-to-metal sealing surfaces between the ball

and the seat. These valves are designed to withstand high temperatures and abrasive media, making them

suitable for applications involving harsh conditions and abrasive fluids. Metal seated ball valves are

more robust and durable than soft seated ones, ensuring a longer service life and reduced maintenance

requirements.

Choosing the Right Valve:

Selecting the appropriate valve type depends on the specific application requirements. Soft seated ball

valves are well-suited for applications where leak-tight sealing and low torque operation are essential.

On the other hand, metal seated ball valves are the go-to choice for applications involving high

temperatures, abrasive media, and extended service life. Consulting with valve experts can help

determine the best-suited valve for each unique situation, ensuring optimal performance and efficiency

in any industrial process.

OEM & ODM service

As a trusted OEM& ODM partner to top valve brands worldwide, CARILO's Ball Valve Team delivers top-notch design drawings and quality. Enjoy the design and excellence of top valve brands at a favorable price.

Applications

Our ball valves excel in various industries, including petrochemicals, industrial gas, chemical, power generation, refining, and pulp&paper.

INSTALLATION, OPERATING, MAINTENANCE AND STORAGE MANUAL

Ensure optimal performance and longevity with our comprehensive manual, reflecting CARILO's dedication to customer satisfaction and excellence.

Download